Functional safety

Safety as an integral part of protecting people, the environment and equipment.

Safety concepts are becoming increasingly important in project planning and are required in all sectors of industry. As early as the basic engineering stage, a comprehensive safety concept should be agreed on the basis of a previous hazard and risk analysis. This is not only about the right choice of components, but also about the correct handling and court-proof documentation of all steps in the safety lifecycle. Due to missing or too late integrated safety concepts, high additional costs are unfortunately often caused.

Compliance with standards such as EN61508/11, VDI/VDE2180, EN ISO13849 or NA106 is a matter of course for us.

However, personnel and plant engineers today have less time available to focus on such work during their operational routines. As a result, the considerable potential for higher plant performance and product quality remains untapped. This is where our innovative solution for you comes in!

Details

“Is protective insulation of a pipeline an example of functional safety?” “My components have been in use for many years. We’ve never had any problems. That’s grandfathered in, isn’t it?” If you have problems answering these questions, you have come to the right place.

The pharmaceutical industry often works with batch processes and complex requirements for operation and functional safety. We are currently seeing a major upheaval in this challenging combination. Our experienced employees are familiar with complex and industry-independent requests.

We are also happy to train your employees on the essential aspects and the right way to deal with this issue.

Overview,

Videos and

more links

Services:

- Project execution based on functional safety management.

- Support through all project phases of the safety lifecycle – from the idea to production.

- Concept creation for your individual project.

- Support as well as implementation of the equipment selection.

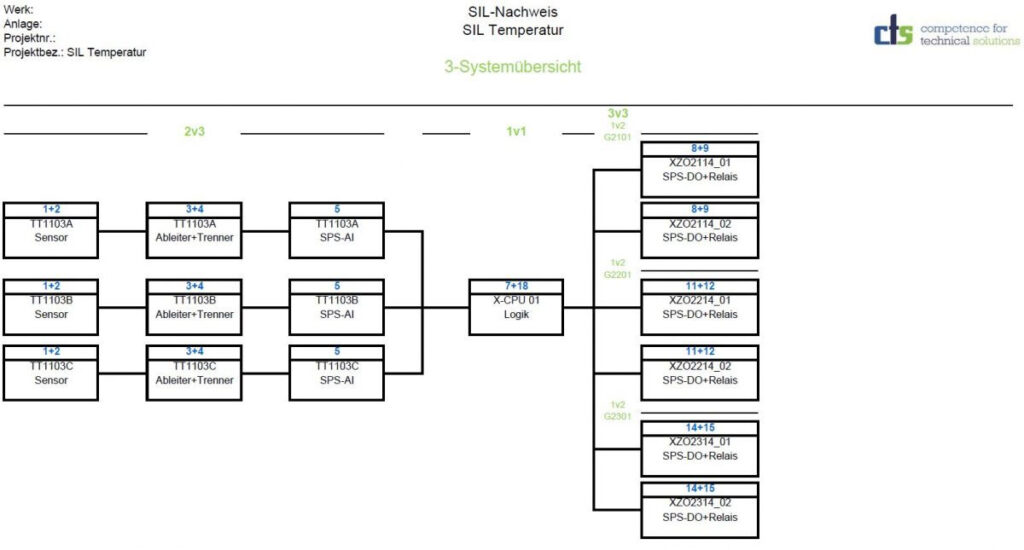

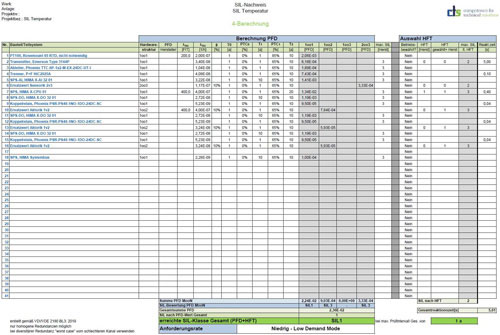

- Creation of SIL verifications taking into account test periods and test depths (consideration of the system architectures, as well as the

probability of failure of the system) - Preparation of the appropriate safety documentation.

- Preparation of initial and recurring inspection instructions.

- Support for acceptance tests internally, or with testing laboratories.

- Training your employees.

Our solutions are customizable. Talk to us!

More. Than. Automation.